Your Best Choice for Pumps, Meters, Valves and Service!

641-456-4802 sales@midwestmeter.com

Liquid Controls®

Since 1956, Liquid Controls® has been dedicated to providing high-quality flow meters and accessories for accurate liquid measurement in custody transfer applications. A combination of in-house engineered designs and a network of full-service distributors ensure customers around the world are supported with technology tailored to each industry’s requirements.

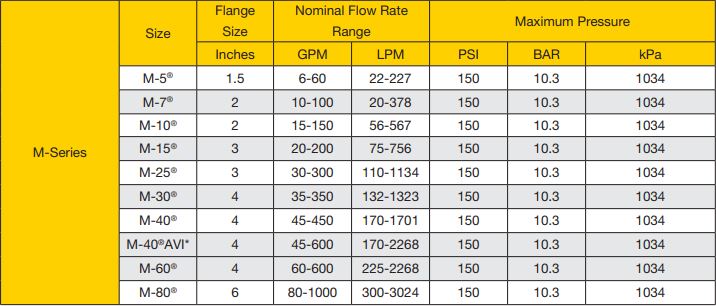

LC® M-Series Meters

M-series meters are the industry standard for bulk custody transfer of refined fuels such as gasoline, diesel, fuel oils, ethylene, glycol, and aviation fuels.

Features and Flow Carts:

• Sustained Accuracy - no metal-to-metal contact inside the measuring chamber means minimal deterioration in accuracy over time, fewer recalibrations, and longer service life.

• Meters conform to NIST and International Weights and Measures accuracy requirements.

• Wide Temperature Range - products can be metered accurately from -40° F (-40° C) to 160° F (71°C).

• Wide Viscosity Range - LC meters can accurately meter products from less than 30 SSU (less than 1 centipoise) to 1,500,000 SSU (325,000 centipoise).

• Maximum Adaptability — right angle design with choice of stock or custom elbows/ fittings provides unequaled mounting flexibility to meet your installation requirements.

• High Pressure rating — Rated to 150psi / 10.5 BAR.

Read More...

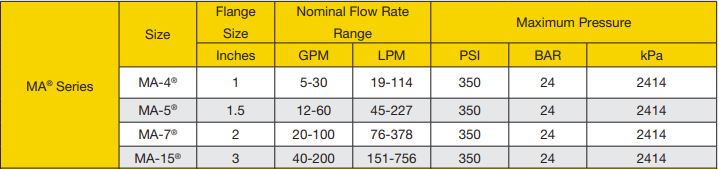

LC® MA Series Meters

MA Series meters class 10 meters are the industry standard for safe and accurate transfer of LPG and anhydrous ammonia (NH3).

Features and Flow Carts:

• Sustained Accuracy - no metal-to-metal contact inside the measuring chamber means minimal deterioration in accuracy over time, fewer recalibrations, and longer service life.

• Meters conform to NIST and International Weights and Measures accuracy requirements.

• Wide Temperature Range - products can be metered accurately from -40° F (-40° C) to 160° F (71°C).

• Wide Viscosity Range - LC meters can accurately meter products from less than 30 SSU (less than 1 centipoise) to 1,500,000 SSU (325,000 centipoise).

• Maximum Adaptability — right angle design with choice of stock or custom elbows/ fittings provides unequaled mounting flexibility to meet your installation requirements.

• High Pressure rating — Rated to 350psi / 24 BAR.

Read More...

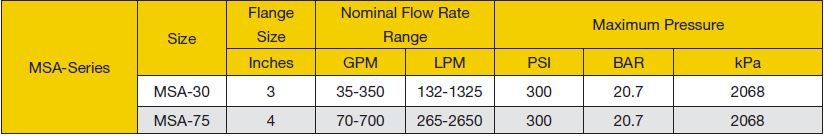

LC® MSA Series Meters

MSA Series Meters are ideal for high flow measurement of LPG loading and unloading tankers, storage tanks, and railcars.

Features and Flow Carts:

• Sustained Accuracy - no metal-to-metal contact inside the measuring chamber means minimal deterioration in accuracy over time, fewer recalibrations, and longer service life.

• Meters conform to NIST and International Weights and Measures accuracy requirements.

• Wide Temperature Range - products can be metered accurately from -40° F (-40° C) to 160° F (71° C).

• Wide Viscosity Range - LC meters can accurately meter products from less than 30 SSU (less than 1 centipoise) to 1,500,000 SSU (325,000 centipoise).

• Maximum Adaptability - right angle design with choice of stock or custom elbows/fittings provides unequaled mounting flexibility to meet your installation requirements.

• High Pressure rating - Rated to 350psi / 24 BAR.

Read More...

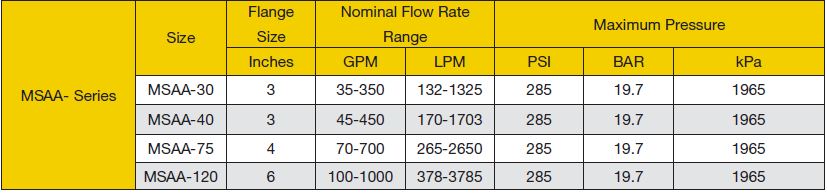

LC® MSAA Series Meters

MSAA Series Meters are ideal for bulk measurement during loading and unloading tanks, railcars, ships, and barges.

Features and Flow Carts:

• Sustained Accuracy - no metal-to-metal contact inside the measuring chamber means minimal deterioration in accuracy over time, fewer recalibrations, and longer service life.

• Meters conform to NIST and International Weights and Measures accuracy requirements.

• Wide Temperature Range - products can be metered accurately from -40° F (-40° C) to 160° F (71°C).

• Wide Viscosity Range - LC meters can accurately meter products from less than 30 SSU (less than 1 centipoise) to 1,500,000 SSU (325,000 centipoise).

• Maximum Adaptability - right angle design with choice of stock or custom elbows/ fittings provides unequaled mounting flexibility to meet your installation requirements.

• High Pressure rating - Rated to 150psi / 10.5 BAR.

Read More...

Mechanical V-Series Valves

V-7 Preset valves are designed to function with a mechanical preset to shut down the flow after a predetermined amount of product is delivered. The preset allows this valve to be mechanically shut down in a single stage or in two-stages. Single stage shut downs are generally utilized with slower flow rates or with more viscous products where hydraulic shock is less of an issue. A two-stage shutdown allows for a slowing of the flow rate before the final positive shutdown, thus avoiding hydraulic shock.

Specifications:

V7 Valves:

• For M-5, M-7 and M-10 Meters

• Classes 1, 2, 3, 4, 8, 14, 16, 18

• Buna or PTFE seals or seals made of Viton®

• Rated to 150psi

• Choose V7 series with M5, M7, M10 meters with mechanical registration.

• The V7 valve indexes in 90° increments with valve outlet facing up, down, back, or front.

V15 and V30 Valves:

• Aluminum V-15 and V-30 Valves For M-15 and M-30 Meters

• Classes 1, 2, 3, 4, 14, 16

• PTFE seals or seals made of Viton®

• Rated to 150psi

• Choose V15 series with M15 meters with mechanical registration.

• Choose V30 series with M30 and M40 meters with mechanical registration.

• Pressure: Up to 150 psi

• The V15 and V30 valve indexes in 90° increments with valve outlet facing up, down, back, or front.

Read More...

Check Valves

Back Check Valves: Eliminates counter advancement and backtracking between deliveries. It works by ensuring the delivery hose is always packed with fuel. Also included built in pressure relief.

Spring Loaded Check Valves: Provides back pressure to increase air/vapor eliminator efficiency and to prevent reverse flow.

Specifications: Materials of Construction: Aluminum (Back Check) and Cadmium plated steel (spring loaded check)

Back check valves are rated to 350psi.

EP Series Valves

The Liquid Controls EP series electro-pneumatic, 2-stage preset valves are designed to control the flow of refined petroleum products including diesel, gasoline, fuel oils, kerosene, ethylene glycol, and lube oils. These valves can be integrated into a complete Liquid Controls positive displacement metering system containing a meter with electronic registration.

Due to the less restrictive design, the EP series provides the benefit of reduced pressure drop and higher potential flow rates, especially when handling higher-viscosity products.

Features:

• Available in 2", 3" and 4" (EP7, EP15)

• Low Pressure Drop

• High Flow Rate

• 2-Stage Preset Valve

• Ideal for High Viscosity Petroleum Products

• Controlled by LCR.iQ, LCR-II or LCR600 registration and a truck’s air system. The LCR.iQ is recommended in lubrication oil applications due to the 16 product calibrations in memory.

Specifications:

• Temperature Rating: -4° to 158°F (-20° to 70°C)

• Pressure Rating: Maximum non-shock working pressure: 150 PSI (10.5 BAR)

• Environmental Rating: Meets ATEX 94/9/EC Requirements

• Max Flow Rate: 132 GPM (500 L/min)

• Viscosity Range: 30 to 20,000* SSU (Consult Factory for Higher Viscosity Liquid Applications)

• Products: Refined Fuels (gasoline, fuel oils, diesel, kerosene, ethylene glycol, and lube oils)

• Safety: Meets PED 97/23/EC Requirements

Materials of Construction:

• Valve Body: Aluminum

• Elastomers: Viton internal O-rings, Buna external O-rings

Solenoids (Available Separately):

• Voltage: 12 VDC

• Maximum Pressure: 145 psi

Two-Stage Operation:

• Reduced Flow Adjustable from 0 to 15% of full flow

• Recommended Regulated Air Pressure: 75-85 PS

Read More...

Electronic Valves

LC electronic valves integrate with LCR.iQ, LCR-II, and LCR 600 Electronic Registers, providing flexible control and greater accuracy preset deliveries.

Solenoid Block Valve:

Provides simple on/off operation typically applied for security purposes to prevent unauthorized operation.

Two-Stage Control Valve:

Provides system security and prevents unauthorized operation. Slow closing microprocessor controlled valve, allows for the preset, net, and/or gross volume, or price when used with LCR.iQ, LCR-II, and LCR 600 registers. At the end of a preset delivery, low flow stage is actuated to eliminate hydraulic shock and improve delivery accuracy.

A2800 Series:

Operation:

Model: Flow Capacity: Max Pressure:

• A2859-11 200 GPM (757 LPM), 350 PSI (24 BAR) *For use with LPG Systems.

• A2847-11 200 GPM (757 LPM), 150 PSI (10 BAR)

• A2848-11 200 GPM (757 LPM), 150 PSI (10 BAR)

Two-Stage Operation:

• S1 first-stage closure for M5, MA5 and M7, MA7 Meters: 6 Gallons (23 liters) minimum.

• S1 first-stage closure for M10 Meters: 10 Gallons (38 liters) minimum.

• S1 first-stage closure for M15 Meters: 12 Gallons (45 liters) minimum.

Temperature: -40° F to +160° F (-40° C to +71° C).

• Maximum non-shock working pressure: 350 PSI (24 BAR)

• Maximum differential pressure: 125 PSI (8.6 BAR).

Pressure Rating Refined Fuels:

• Maximum non-shock working pressure: 150 PSI (10 BAR)

• Maximum differential pressure: 100 PSI (6.9 BAR).

Electrical Data:

• Solenoids: +12 volt DC coils (+24 volt DC optional).

• Current: 1 Amp maximum per solenoid.

Enclosure:

• Explosion-proof, UL approved for NEMA 7

• Meets requirements for Class I, Division 2, Group C and D hazardous locations.

E-7 Valve Specifications:

• Environmental Rating: NEMA 4X

• Safety: Designed to meet Class I, Division 2 requirements

• Temperature Rating: -40° to 160°F (-40° to 71°C)

Pressure Rating:

• Maximum non-shock working pressure: 150 PSI (10.3 BAR)

• Maximum differential pressure: 100 PSI (6.9 BAR)

• Flow Range 150 GPM (568 L/min) for 30 SSU products

• Viscosity Range: 30 to 100 SSU

Solenoids:

• Voltage: +10.2 to 13.6 VDC (Optional Voltage: +20.4 to 27.2 VDC)

• Current: S1: 1 Amp, S2: 2 Amps maximum

Two-Stage Operation: Minimum recommended volume for trickle stage flow:

• M5 Meters: 6 gallons (23 liters)

• M7 Meters: 10 gallons (38 liters)

• M10 Meters: 15 gallons (57 liters)

Read More...

Differential Valves

Differential/Air Check valves are placed on the outlet side of a meter system and work in conjunction with the system’s air/vapor eliminator to stop the flow of product through the meter until the air/vapor is eliminated. In order to do this, the air/vapor eliminator and the valve are piped together at installation.

Differential/Air Check valves are normally closed, but when the pump starts and pushes product into the system, the valve spring will give way to the flow pressure. In order to keep the valve closed when air/vapor is being expelled from the air/vapor eliminator, the air/vapor from the air/vapor eliminator is routed through the piping to the back side of the valve spring. The combined force of the expelled air/vapor and the strength of the spring keep the valve closed until the air/vapor is eliminated.

Materials of Construction:

• Aluminum

• Standard 2″ aluminum valve is spring loaded and designed to fail closed.

• Provides a constant 15 PSI differential pressure and controls flow when vapor is sensed.

• The 511-series differential valve is available with an adjustable differential pressure setting of 5 to 16 PSI.

• Available in ductile iron or cast steel in sizes of 2″, 3″, 4″ or 6″ flanges.

• Typically used with our MS-series meters and accessories.

Read More...

Optical Air Eliminators

Optical air eliminators detect changes in refractive index to detect air. An optical air eliminator is more responsive than our mechanical air eliminator and less product ends up in your external catch tank.

The Liquid Controls Optical Air Eliminator is designed for use with LCR.iQ, LCR-II, or LCR 600 Electronic Registers.

Features:

• Provides for the efficient elimination of air and vapor with virtually no moving parts

• An optical sensor is used to monitor the liquid level

• The presence or absence of liquid at the sensor level activates or deactivates a solenoid located at the top of the air eliminator. The Optical Air Eliminator requires the use of a solenoid operated valve.

When liquid rises to the optical sensor level, the solenoid closes and prevents continued venting to atmospheric pressure, and the electronic control valve at the meter outlet opens so that a delivery may continue. This functionality ensures that only liquid passes through the meter.

The optical air eliminator is designed to work with Liquid Controls meters for applications measuring refined petroleum products and LPG.

Specifications:

• Materials of construction: Aluminum

• Environmental Rating: NEMA 4X

• Safety: Designed to meet Class I, Division 2 requirements

• Temperature Rating: -40° to 160°F (-40° to 71°C)

• Maximum Non-Shock Working Pressure

• 150 PSI (10.3 BAR)

• 350 PSI (24 BAR)

• Maximum Differential Pressure: 100 PSI (6.9 BAR)

• Solenoids Voltage: +10.2 to 13.6 VDC (Optional Voltage: +20.2 to 27.2 VDC)

• Current: 1 Amp maximum

• Optical Sensor Voltage: +10 to +28 VDC

• Current: 0.05 Amp maximum

Read More...

Steel Air Eliminators

Liquid Controls mechanical air and vapor eliminators remove air and vapor from metering systems. Removing the air and vapor from a metering system increases the accuracy of the meter by allowing only liquid to pass through the meter.

At installation, LC mechanical air and vapor eliminators are piped to a storage tank to provide a pathway and a receptacle where the evacuated air vapor can be deposited. After the air (or vapor) has left the metering system, mechanical air and vapor eliminators seal off the pathway to prevent liquid from entering the storage tank.

Features:

• For use MSA and MSAA Series Steel case Meters

• Materials of construction for Classes 1, 10, 14, and 16 applications

• For installation on FS and FSA Series Steel Strainers

• All steel air eliminators are rated 350PSI

Read More...

Mechanical Air Eliminators

Removing the air and vapor from a metering system increases the accuracy of the meter by allowing only liquid to pass through the meter for measurement.

At installation, LC mechanical air and vapor eliminators are piped to a storage tank to provide a pathway and a receptacle where the evacuated air and vapor can be deposited. After the air (or vapor) has left the metering system, mechanical air and vapor eliminators seal off the pathway to prevent liquid from entering the storage tank.

Features and Specifications:

Aluminum 150PSI for use with M5, M7, M10, M15, M25, M30, M40 and M60 Meters.

•Materials of construction for Classes 1, 2, 3, 4, 14, 15, 16 and 30 applications.

•Designed for installation of F7, F15 and F30 Strainers.

Aluminum high pressure for use with 350 PSI, MA4, MA5, MA7 and MA15 Meters.

•Materials of construction for Class 10 LPG Service.

•Other Classes available on special order, including class 12 NH3. Relief valve provided as required for Classes 10 and 12 applications.

Stainless steel 150psi for use with M5 and M7 Meters.

•Materials of construction for Class 8 and 18 applications.

•Designed for installation on F7, Class 8 Strainer.

Read More...

Bulk Plant Air Eliminators

At installation, LC mechanical air and vapor eliminators are piped to a storage tank to provide a pathway and a receptacle where the evacuated air and vapor can be deposited. After the air (or vapor) has left the metering system, mechanical air and vapor eliminators seal off the pathway to prevent liquid from entering the storage tank.

Now available with an optical sensor, the Single Head Bulk Plant Air Eliminators — provide a new bulk plant air elimination solution that simplifies installations, reduces maintenance, and removes problematic slugs of air. The Single Head Bulk Plant Air Eliminator with Optical Sensor marks the latest breakthrough in the four-decade long evolution of Liquid Controls’ air eliminators. It is ideal for eliminating air from refined fuels applications where product is metered into storage from a truck-mounted pump.

The optical sensor provides the same functionality of the dual head mechanical air eliminator in a single head design. The optical sensor, when used with an electronic register provides a signal to a downstream control valve to shut down in the presence of a large volume of air. This prevents the air from being metered. The high mount air eliminator evacuates the air until the optical sensor does not sense the air. In the presence of liquid, the valve now opens and the product flows through the meter.

Features and Specifications:

• For use in any 150 PSI working pressure system using aluminum M-Series or steel MS-Series Meters.

• Choice of 3", 4", 6" and 8" ANSI flanged connections.

• Shown is the dual head mechanical model providing twice the normal venting capacity.

• Dual head model is most effective when utilizing a differential valve.

• 3", 4", 6" or 8" Raised Face ANSI Flanges

• Working pressure: 150psi

Read More...

FS and FSA Series Steel Strainers

A strainer installed on the inlet side is necessary even when a coarse strainer on the upstream side of the pump is included in the system. Strainers are not meant to be used as a system filter but as limited protection for the meter element itself. Strainer baskets are available in 20, 40, 80 or 100 mesh.

Specifications:

FS-Series

• 150 PSI

• 150lb. ANSI Flange

FSA-Series

• 300 PSI

• 300lb. ANSI Flange

• 3", 4″ and 6" sizes, made of steel

• Straight-through flow standard

• When air eliminator is used, cover is replaced with air eliminator cover assembly.

Read More...

2" F7/ FA7 Strainers

A meter strainer installed on the inlet side is necessary even when a coarse strainer on the upstream side of the pump is included in the system. Strainers are not meant to be used as a system filter but as limited protection for the meter element itself. Strainer baskets are available in 20, 40, 80, 100, 150 mesh.

Specifications:

• Materials of Construction

• Aluminum

• Stainless Steel

• 2" (1 1/2″ optional) 150 PSI, Aluminum for M-5 and M-7 Meters. Materials of construction for Classes 1, 2, 3, 4, 14, 16 applications. Supplied with cover or without cover when air eliminator is used.

• 2" (1 1/2″ optional) 150 PSI, choice stainless steel for M-5 and M-7 Meters. Materials of construction for class 8 or 18 applications. Easily adapted for air eliminator mounting when required.

• 2" (1 1/2″ optional) 350 PSI, high pressure aluminum for MA-5 and MA-7 Meters. Materials of construction for Class 10 LPG applications. Other classes available on special order including Class 12 for NH3. Supplied with cover or without cover when air/vapor eliminator is used. Relief valve provided as required for Class 10 and 12 services.

Read More...

3" F15 / FA15 Strainers

A meter strainer installed on the inlet side is necessary even when a coarse strainer on the upstream side of the pump is included in the system. Strainers are not meant to be used as a system filter but as limited protection for the meter element itself. Strainer baskets are available in 20, 40, 80, 100 or 150 mesh.

Features:

• 3" 150 PSI, Aluminum for M15, and M25 Meters

• Materials of construction for Classes 1, 2, 3, 4, 14, and 16 applications.

• Supplied with cover or without cover when air eliminator is used.

• 3" 350 PSI, Aluminum for MA15, Class 10

Read More...

High Capacity Strainers

A meter strainer installed on the inlet side is necessary even when a coarse strainer on the upstream side of the pump is included in the system. Strainers are not meant to be used as a system filter but as limited protection for the meter element itself. Strainer baskets are available in 20, 40, or 80 mesh.

Features:

• F7 High Capacity Aluminum Strainer, for use with 2″ M7 and M10 Class 1 meters.

• F15 High Capacity Aluminum Air Eliminator / Strainer assembly for use with 3″ M15 and M25 Class 1 meters.

• All High Capacity Strainers are rated to 150PSI

• Designed specifically for refined fuel delivery truck applications where split compartment testing is required.

Read More...

4" F30 Strainers

A meter strainer installed on the inlet side is necessary even when a coarse strainer on the upstream side of the pump is included in the system. Strainers are not meant to be used as a system filter but as limited protection for the meter element itself. Strainer baskets are available in 20, 40, 80 mesh.

Features:

• 4" (3" optional) 150psi aluminum for M30 and M40 Meters.

• Materials of construction for Classes 1, 2, 3, 4, 14, and 16 applications.

• Supplied with cover or without cover when air eliminator is used.

Read More...